ABOUT DAILUEN

Dailuen, established in 1995, specializes in the research, production, and sales of polyester and nylon fabrics, aiming to offer durable, sustainable materials.

Dailuen emphasizes urban leisure, functional outdoor, and recycled fabrics, operating two mega-factories that handle a complete production cycle from spinning to printing, covering an area of 300,000 square meters with an annual capacity of 80 million yards and employing over 700 staff.

Dailuen is a proud supplier to customer-trusted brands such as THULE, Samsonite, Dell, HP, FILA, and Li-Ning.

International Certifications

OEKO-TEX Standard 100: Confidence in Textiles Certification

Global Recycled Standard: Recycled Standard Certification

BSCI: Business Social Compliance Initiative Certification

ISO 9001: Quality Management System Certification

ISO 14001: Environmental Management System Certification

ISO 45001: Occupational Health and Safety Management System Certification

Super Factory

SHOWROOM: Shenzhen / Huizhou / Suzhou / Yongzhou

Yongzhou

2nd Hongfeng Rd, Qiyang Industrial Park, Yongzhou, Hunan

Huizhou

Foling Industrial Park, Huizhou, Guangdong

Almost 100% of our products are independently researched and produced by our company.

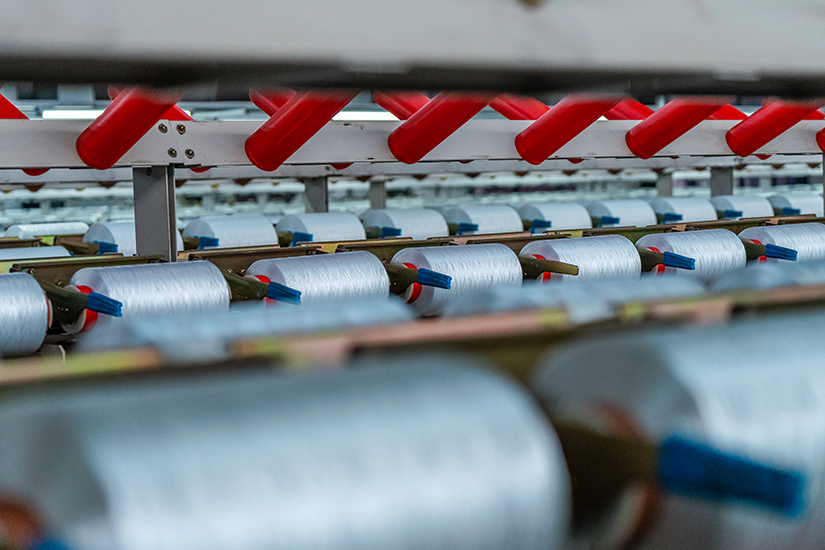

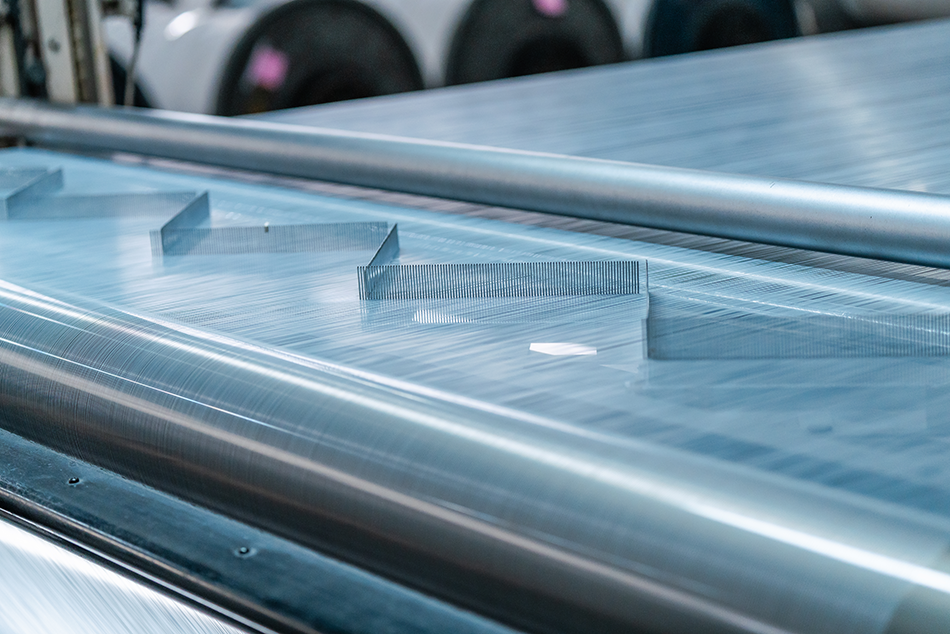

Since Dailuen’s establishment, we have focused on the synthetic fabric industry chain, leveraging years of research and development cooperation to establish a vertically integrated layout spanning spinning, weaving, printing and dyeing, and finishing processes.

With two super factories under our umbrella, we cover six major industry chains: spinning, weaving, dyeing, finishing, coating, and printing, providing customers with one-stop solutions.

With a total area of 300,000 square meters, our factories have an annual capacity of 80 million meters, with a total investment of $100 million. We have passed factory audits by VF Group and THULE. We are certified by OEKO-TEX, GRS 4.0, BSCI, ISO 45001, ISO 14001, and ISO 9001. We are strategic partners with KORRUN.

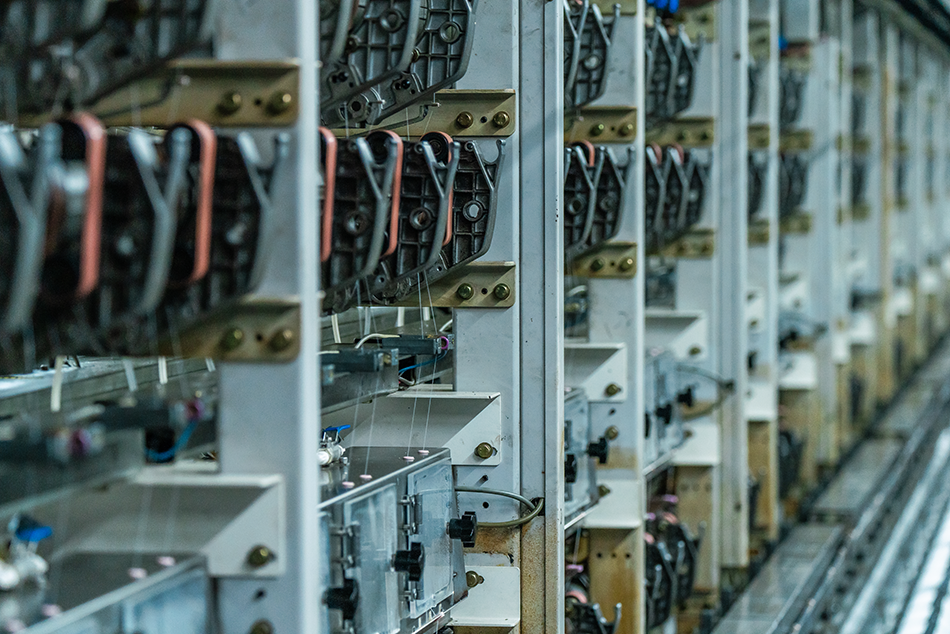

Spinning workshop

Weaving workshop

Equipped with 700 water-jet and air-jet looms

Dyeing and post-processing workshop

Warehousing

We have a complementary warehouse covering an area of 5000 square meters, managed using ERP systems and barcode recognition technology.

Through ERP digitization, we establish a complete information-based quality traceability chain from the issuance of business orders to shipment delivery. Within our warehousing process, we utilize metal pallets instead of plastic or wooden ones to prolong the lifespan of container equipment. Furthermore, we employ electric forklifts to reduce emissions during material transportation.